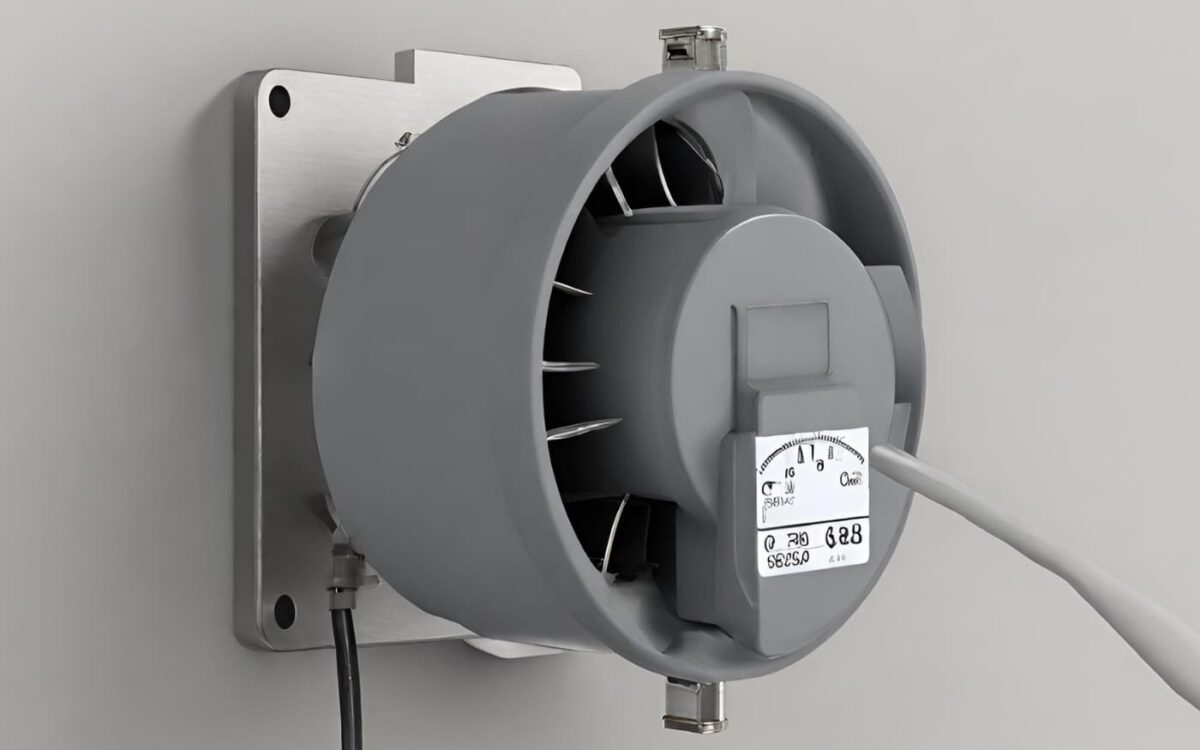

As far as HVAC (Heating, Ventilation, and Air Conditioning) systems go, precise temperature control is essential for comfort, energy efficiency, and system performance. Duct temperature sensors play a crucial role in achieving this control. Belimo duct temperature sensors, among others, are trusted components in the industry. Today we will explore the various types of duct temperature sensors available to help you make informed choices.

Types of Duct Temperature Sensors

Duct temperature sensors come in various types, each with its own set of advantages and disadvantages. These sensors are designed to accurately measure the temperature of the air flowing through HVAC ducts, enabling precise control of heating and cooling systems. Let’s delve into the pros and cons of some common types of duct temperature sensors.

Advantages of Thermocouple Sensors

Thermocouple duct temperature sensors are known for their accuracy and durability. They can operate in a wide temperature range, making them suitable for diverse HVAC applications. Their simplicity and reliability are key advantages, and they are often cost-effective choices.

Disadvantages of Thermocouple Sensors

While thermocouple sensors offer many benefits, they are not without drawbacks. One limitation is the need for signal conditioning due to their low output voltage. Additionally, they can be sensitive to electromagnetic interference, affecting their accuracy. Cost can also be a consideration, as high-temperature thermocouples can be relatively expensive.

Advantages of RTD Sensors

Resistance temperature detector (RTD) duct temperature sensors are favored for their accuracy and stability. They provide precise temperature measurements, making them suitable for critical HVAC applications where precision is paramount. RTD sensors are known for their long-term reliability.

Disadvantages of RTD Sensors

Despite their advantages, RTD sensors have some limitations. They tend to be more expensive compared to other sensor types, which can impact the overall cost of an HVAC system. Additionally, RTDs have a limited temperature range compared to thermocouples, and their response times can be longer.

Advantages of Thermistor Sensors

Thermistor duct temperature sensors are valued for their sensitivity, making them ideal for applications where rapid temperature changes need to be detected. They are often cost-effective and are commonly used in HVAC systems where accuracy is important but not necessarily critical.

Disadvantages of Thermistor Sensors

However, thermistor sensors may not be suitable for extreme temperature environments due to their limited range. They can also have a shorter lifespan compared to some other sensor types, necessitating more frequent replacements in certain cases.

Advantages of Infrared Sensors

Infrared duct temperature sensors offer non-contact temperature measurement, making them useful in specific HVAC applications. They provide rapid temperature readings without physically contacting the air or surface, which can be advantageous in certain situations.

Disadvantages of Infrared Sensors

Despite their speed and non-contact nature, infrared sensors have their downsides. They can be sensitive to dirt and dust, which may affect their accuracy over time. Additionally, infrared sensors can be relatively expensive compared to some other options.

Selecting the Right Sensor for Your HVAC Needs

When choosing a duct temperature sensor for your HVAC system, it’s crucial to consider the specific requirements of your application. Here are some factors to keep in mind:

- Accuracy: If your HVAC system demands precise temperature control, RTD sensors may be the best choice due to their exceptional accuracy. They provide highly reliable and consistent readings, making them suitable for critical environments where precision is paramount. Thermocouples are also accurate but may require additional calibration to achieve the desired level of precision.

- Temperature Range: Consider the operating temperature range of your system. Thermocouples excel in extreme temperatures, both high and low, making them ideal for applications where temperature variations are significant. RTDs fall somewhere in between, offering good performance in a moderate temperature range. Thermistors are better suited for applications with relatively stable temperature conditions.

- Budget: Your budget can influence your choice of sensor. Thermocouples are often cost-effective, making them a popular choice for budget-conscious projects. RTDs tend to be more expensive due to their precision and stability. Thermistors are a middle-ground option in terms of cost, offering a balance between accuracy and affordability.

- Response Time: In applications where rapid temperature changes need to be detected quickly, thermistors and infrared sensors offer faster response times compared to RTDs and thermocouples. Thermistors are highly responsive to temperature changes and are suitable for applications that require real-time adjustments.

- Environmental Factors: Consider the impact of environmental factors on sensor accuracy. Infrared sensors, for example, are highly sensitive to dirt and dust, which may affect their accuracy over time. Regular cleaning and maintenance may be necessary to ensure consistent performance. Thermistors are relatively less sensitive to environmental factors, making them a good choice for many HVAC applications.

- Long-Term Reliability: For critical applications where sensor longevity is essential, RTDs are known for their long-term reliability. They have a stable resistance over time and are less prone to drift. However, thermocouples can also provide durability if properly maintained and calibrated.

- Integration and Compatibility: Ensure that the selected sensor type is compatible with your HVAC system and can be easily integrated into the control and monitoring systems. Consider the availability of signal conditioning and amplification equipment if needed for certain sensor types.

Conclusion

In conclusion, selecting the right type of duct temperature sensor for your HVAC system involves weighing the pros and cons of each sensor type while considering your specific requirements. The choice ultimately depends on factors such as accuracy, temperature range, budget, response time, environmental conditions, and long-term reliability. Belimo duct temperature sensors, among other reputable options, offer a range of choices to cater to diverse HVAC needs. Understanding these factors will help you make informed decisions to optimize temperature control in your HVAC system.